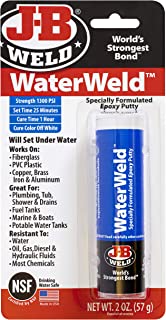

Marine Epoxy Stick by White Oz – WaterWeld Specialist

A practical solution for quick and sturdy repairs, White Oz’s Marine Epoxy Stick, particularly formulated for water exposure, ensures a solid and lasting fix. This WaterWeld product offers versatility in dealing with a broad range of materials.

This product’s beauty lies in its convenience and efficiency. It adheres securely to surfaces such as fibreglass, metal, wood, concrete, and many others, giving you flexibility in its use. It even performs impressively under water, a feature not many adhesives can boast of. Hence, it’s the ultimate go-to epoxy stick for both marine enthusiasts and professionals alike.

The White Oz WaterWeld Epoxy Stick can be moulded into any shape to suit your repair needs, filling in gaps or replacing lost parts of the material. Once it sets, it becomes as hard as steel, providing excellent strength and longevity to your repair work. The best part? It’s resistant to heat, chemicals, and rot, thereby ensuring your fixes last even in harsh conditions.

Application is simple and mess-free. Cut, knead, and apply the putty to the affected area. In just an hour, it cures to a light white colour that can be sanded, drilled, filed, tapped, machined, and painted. Now, repairing a leak or a hole has never been this straightforward!

A: Yes, White Oz WaterWeld Epoxy Stick adheres effectively to a variety of materials, including most plastics.

Q: How long does it take for the epoxy to fully cure?

A: Typically, the product cures in about an hour, after which it can be sanded, drilled, and painted as needed.

Q: Can it withstand high temperatures?

A: Yes, this putty epoxy is resistant to heat, providing durability even in high-temperature environments.

Q: Is it safe to use underwater?

A: Absolutely. White Oz’s Marine Epoxy Stick is specially formulated to function efficiently even when used underwater.